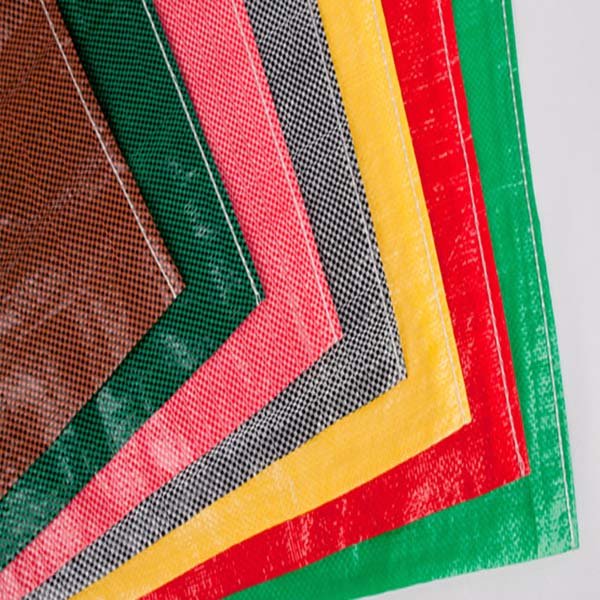

Woven bags

قال ChatGPT:

Woven polypropylene (PP) strips are a type of plastic fabric made from polypropylene resin, known for their durability, lightweight nature, and resistance to water and chemicals.

They are used in a wide range of industrial and consumer applications, such as packaging, construction, and protective coverings.

Manufacturing Process

The production of woven polypropylene strips involves several steps:

Extrusion: Polypropylene granules are melted and formed into fine threads.

Weaving: These threads are woven together using circular looms to create a flat or tubular fabric.

Lamination (Optional): A lamination layer can be added to increase moisture resistance.

Cutting: The woven fabric is cut into the desired size and shape for making bags or covers.

Properties and Features

Strength and Durability: Woven strips have high tensile strength, making them tear-resistant and highly durable.

Lightweight: Despite their durability, they are lightweight, making handling and transport easy.

Moisture Resistance: The fabric provides an effective barrier against moisture, especially when laminated.

Chemical Resistance: The strips resist many chemicals and acids, enhancing their industrial applications.

Recyclable: Made from recyclable plastic, contributing to reduced plastic waste.

Common Uses

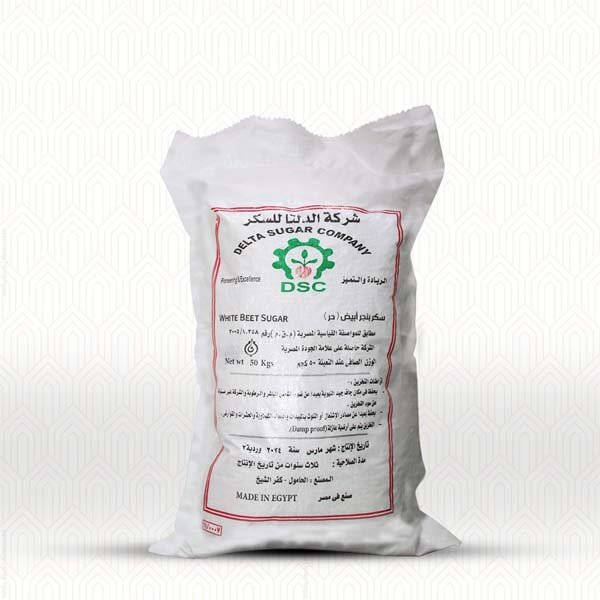

Packaging: Used in woven bags for packaging agricultural products such as grains, rice, sugar, as well as feed and cement.

Construction: Used as protective coverings on construction sites or as filtration barriers in civil engineering projects.

Agriculture: Used as mats to reduce weed growth in fields.

Consumer Goods: Used in making reusable bags and tote bags